Author: Site Editor Publish Time: 2025-08-20 Origin: Site

Facility managers, engineers, and building owners need to follow some rules for a generator room. Important things are:

Fire safety steps for emergencies

Good ventilation to keep air cool and dry

Enough space for machines and people to move

Following codes for safety and trust

A standby generator room helps the emergency power system work. They should ask local experts to meet special project needs.

Leave at least 36 inches of open space around generators. This helps people work safely and lets air move well.

Build generator rooms with strong fire-rated walls and doors. These protect people and equipment from fire.

Make sure the room has good ventilation. Keep the temperature between 64°F and 80°F. Keep the humidity between 40% and 60%.

Add soundproofing and vibration isolation to the room. This lowers noise and keeps people in the building safe.

Test generators often. Do weekly checks, monthly partial load tests, and yearly full load tests. This makes sure emergency power works when needed.

When you design a generator room, you must know the generator room size requirements. These rules help keep people safe and make maintenance easier. They also make sure the room follows codes. The right size lets air move well and lowers risks.

All generator rooms need to meet minimum clearance standards. These clearances let workers reach equipment for checks and repairs. They also help air flow around the generator.

You need at least 36 inches of space around each generator for maintenance, as NFPA 110 says.

Outdoor generator units must have at least 5 feet of space from building openings or walls that can burn, following NFPA 37.

Manufacturer guidelines often say to keep at least five feet from any building or flammable thing.

Both codes and manufacturers say good ventilation and exhaust systems are important.

Raised platforms should be at least 36 inches wide from the generator rails so workers can do full maintenance.

Tip: Always look at local codes and manufacturer instructions before you finish the generator room size requirements. Some rules may be stricter depending on the generator type or fuel source.

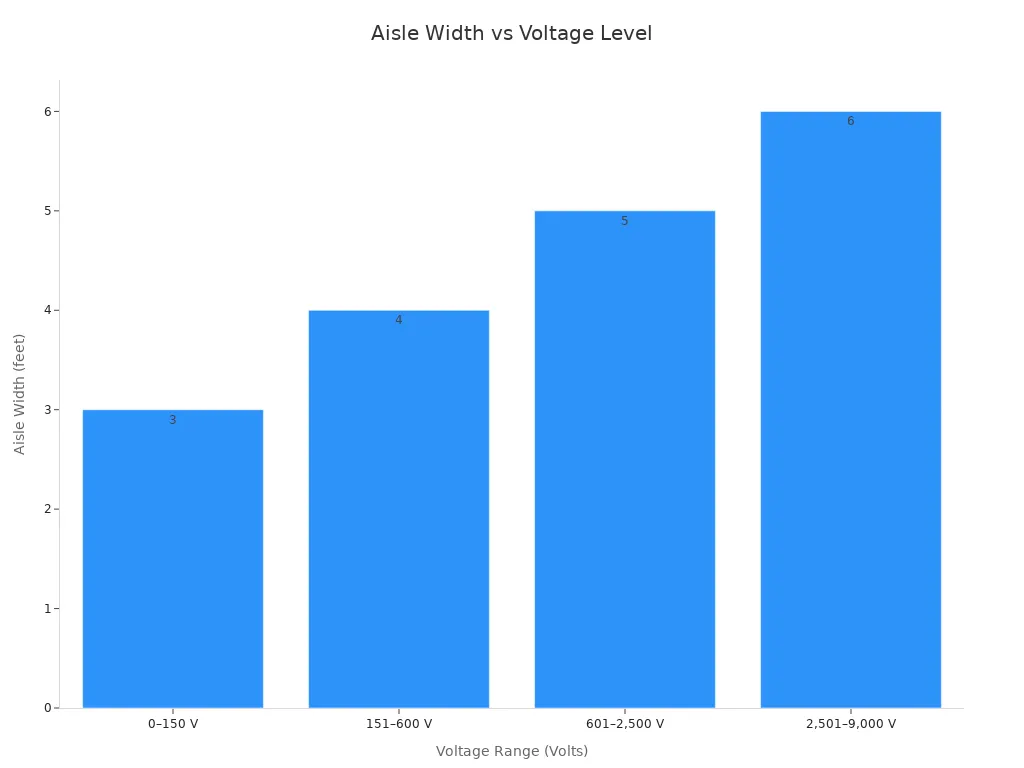

Aisle space is very important for generator room size requirements. It lets workers move safely and helps stop accidents. The National Electrical Code (NEC) gives clear aisle width rules based on voltage.

Voltage Range (Volts) | Minimum Aisle Width (feet) | Notes on Clearance |

|---|---|---|

0 – 150 | 3 | Minimum depth and clearance on all sides: 3 feet |

151 – 600 | 4 | Clearance on side opposite live parts: 4 feet |

601 – 2,500 | 5 | Increased clearance for higher voltage equipment |

2,501 – 9,000 | 6 | Highest clearance for very high voltage equipment |

If equipment is over 1,200 amps and wider than 6 feet, exits must be at both ends of the room.

The side clearance must be at least 30 inches or as wide as the equipment, whichever is bigger.

Height clearance in front of equipment must be at least 6.5 feet or as tall as the equipment.

A generator room should let two people walk past each other easily. This is helpful in emergencies and for regular checks.

The layout of a generator room affects safety, maintenance, and how well things work. Good design follows generator room size requirements and makes it easy to reach all equipment.

Put generators in their own rooms with fire-rated walls.

Keep clear paths to fuel tanks and pipes for maintenance.

Do not store things that can burn in the generator room.

Put manual remote shutoff valves for fuel pumps where they are easy to reach.

Make sure fuel transfer pumps only run when the generator is on.

Add fire sprinkler protection that works at the highest temperature expected.

Place the generator room next to the power distribution room for easier wiring.

It is better to put the room on the first floor for good ventilation and smoke exhaust, but many buildings use basements. In basements, make sure there is strong ventilation and good access.

One wall should face outside to help with ventilation and smoke exhaust.

Do not put the room in damp places or under water pipes.

The layout of the machine room should let people move easily, do safe maintenance, and leave quickly if needed. Local codes and manufacturer guidelines help decide the final design. They make sure the generator room meets all generator room size requirements and works safely.

Good ventilation and airflow help keep a generator room safe. The design should let air move and heat leave the room. This protects equipment and people. Temperature, humidity, and air movement are all important for cooling.

A generator makes a lot of heat when it runs. The room must stay cool so nothing gets damaged. Experts say the temperature should be between 64°F and 80°F. It should never go over 104°F. If it does, the generator loses power. For every 18°F above 104°F, the generator can lose up to 15% of its power. At 122°F, the chance of failure is higher. High heat also makes electrical parts wear out faster. Overheating can cause burns or shut down the system.

Note: Always use good ventilation to keep air clean and cool. This helps the generator get rid of heat and keeps it working well.

A good room uses fans, vents, or louvers to move hot air out. Cool air comes in from outside. It is best if one wall faces outside. This makes it easy to put in exhaust fans and vents.

Humidity control keeps the generator safe from rust and electrical problems. The best humidity range is 40% to 60%. This stops water from building up on wires and metal. It also keeps insulation strong and stops condensation.

High humidity causes rust on terminals and panels.

Water lowers insulation resistance and can cause leaks.

Condensation from temperature changes may cause faults.

Industrial dehumidifiers help keep humidity steady.

If humidity gets too high, water can get stuck in insulation. This is hard to fix and can hurt the generator over time. When the generator is off, air-cooled units have more moisture problems. Heaters or dry air help stop this. Keeping humidity right makes the generator last longer.

Humidity Level | Effect on Generator Room |

|---|---|

Below 40% | Risk of static electricity |

40% - 60% | Ideal for equipment protection |

Above 60% | Corrosion, insulation failure |

Air movement helps remove heat from the engine and exhaust. It also brings in fresh air for cooling. Generator rooms need lots of air changes each hour. Big rooms may need up to 60 air changes every hour. This means the air gets replaced every minute. High airflow can make the room feel windy, but it is needed.

Exhaust pipes add more heat to the room.

Large generators give off a lot of heat.

Some designs use remote radiators to lower airflow needs.

Some systems use airflow rates of 53,000 cfm or more.

Generator Size | Typical Air Changes per Hour | Notes |

|---|---|---|

Small | 4 - 6 | Baseline for small engines |

Medium | 10 - 30 | More heat, more airflow |

Large | 30 - 60+ | High heat, wind tunnel effect |

Tip: Always match air movement to the generator size and heat. Put exhaust vents and fans on an outside wall for best results.

Good ventilation and heat dissipation keep the generator room safe. This protects equipment, lowers risks, and helps the generator work well.

NFPA 110 has strong rules for fire safety in generator rooms. Every indoor generator room needs walls and doors that can stop fire for two hours. The room must be separate from the rest of the building. Only emergency power supply equipment can go inside. You cannot put other things or systems in the room. If air vents go through the walls, they must also stop fire for two hours. This keeps the room safe from fire. These rules are the same for all generator rooms, no matter the building type.

The right materials help with fire safety and noise control. Concrete Masonry Units (CMU) are good for generator room walls. They are strong and can stop fire for up to four hours. CMU walls also help block loud sounds from the generator. Some rooms use walls with many layers. These layers can have thick insulation, special foam, and noise-blocking parts. All materials must not catch fire easily. Doors should close tightly to keep sound in. Weather-stripping helps stop noise from escaping. Air systems can use baffles or angled pipes to lower noise but still let air move.

Advantage Category | Description |

|---|---|

Structural Strength | CMU walls hold heavy things and stand up to wind. |

Fire Resistance | Fire ratings from 1 to 4 hours make generator rooms safer. |

Durability | CMU walls last a long time and do not need much care. |

Sound Attenuation | CMU blocks soak up and stop noise, so other rooms stay quiet. |

Versatility | CMU units let you add pipes and wires, so they fit many designs. |

Generator rooms must stay apart from other parts of the building. The rules say to use fire barriers or floors that stop fire for two hours. Transfer switches need their own rooms with the same fire rating. Air vents must go straight outside. Ducts must match the room's fire rating and cannot have dampers. Power lines from the generator must run by themselves. These steps help keep the generator room safe and protect the rest of the building.

Tip: Always use insulation that does not burn or slows fire. This gives more safety and meets the rules.

Generator rooms can be very loud. This noise can bother people in the building. It can also affect neighbors. Facility managers need to lower the noise. They must keep sound within the law. This helps everyone stay comfortable.

Sound attenuation means making the generator quieter. There are many ways to do this:

Sound-attenuated enclosures use panels with many layers. The outside is solid. The inside has materials that soak up sound.

Mufflers and noise silencers make the engine exhaust quieter. They come in different types. Some use sound waves. Some soak up sound. Some do both.

Acoustic insulation inside the enclosure soaks up sound that bounces around.

Cooling air attenuation baffles make airflow noise less.

Acoustic barriers and landscaping help block noise. Thick bushes or trees can help too.

Regular maintenance keeps mufflers and filters working well.

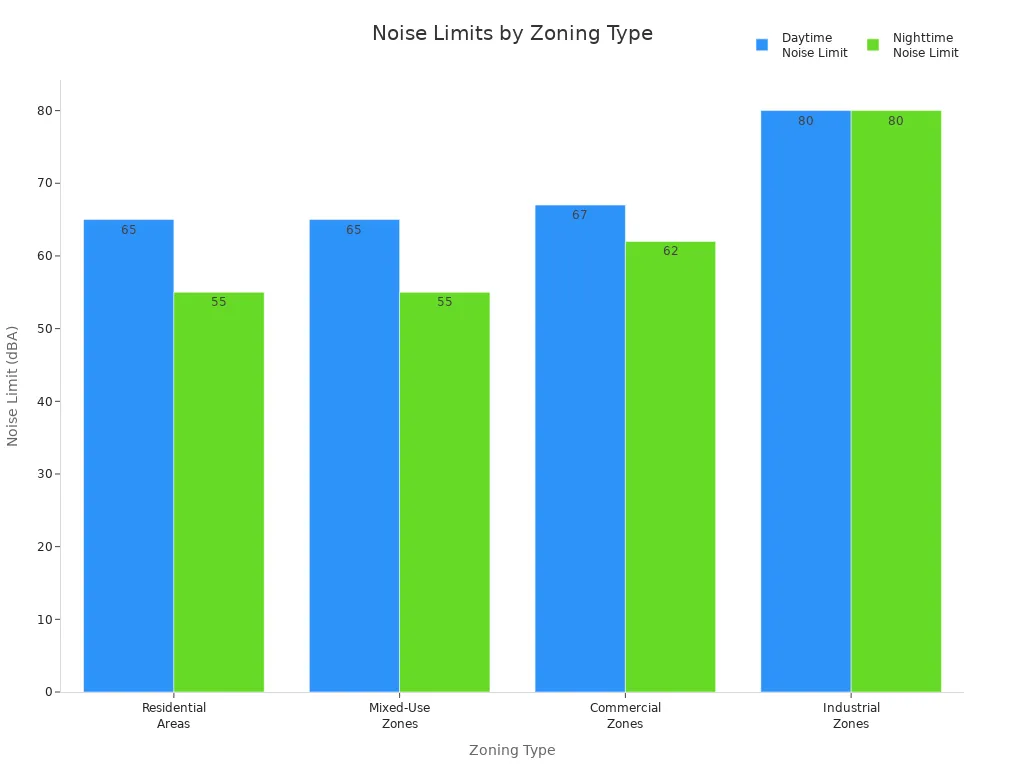

Local rules set noise limits for generator rooms. Facility managers must check these rules first. They need to know the limits before planning soundproofing. The table below shows common noise limits for day and night in different zones:

Zoning Type | Daytime Noise Limit (dBA) | Nighttime Noise Limit (dBA) |

|---|---|---|

Residential Areas | ~65 | ~55 |

Mixed-Use Zones | ~65 | ~55 |

Commercial Zones | ~67 | ~62 |

Industrial Zones | 80 | ~80 |

Tip: Always check local noise rules before putting in generators.

Vibration isolation stops noise from moving through the building. There are different ways to do this:

Vibration pads and springs stop high-frequency vibrations. Pads made of neoprene rubber and cork work better than just one material.

High-compliance springs with at least 2 inches of compression stop low-frequency vibrations. Caged springs help keep things steady.

Using both pads and springs works well for most places.

Some places use an inertia base. This is a heavy steel frame filled with concrete. It weighs at least 150% of the generator set. Springs between the generator, inertia base, and floor help stop vibrations.

Flexible metallic braided pipes and conduits stop vibrations from moving through hard connections.

Seal all holes in enclosures and inertia bases with soft caulking that does not get hard.

Facility managers should work with manufacturers on vibration isolation. This makes sure the system controls noise as needed.

A good exhaust system keeps people and equipment safe. It moves dangerous gases away from air intakes, windows, and doors. The system must handle heat so nothing gets damaged. Mufflers and other parts help lower noise and spread gases safely. Regular checks find leaks, rust, or loose parts. Taking care of mufflers and heat shields keeps noise down and protects equipment from heat. For indoor setups, carbon monoxide monitors and strong fans stop toxic gas from building up. The smoke exhaust pipe should go straight to an outside wall for safe release.

Key requirements for exhaust system design:

Put exhaust pipes far from places where people are.

Control heat to keep parts safe.

Use mufflers that meet noise and safety rules.

Check for leaks and blockages often.

Take care of mufflers and heat shields.

Watch for carbon monoxide and use good fans inside.

Fuel storage helps the emergency power supply work. It must follow strict safety rules. Generators work best outside or in places with good airflow. Inside, keep at least 5 feet between the generator and things that can burn. Use fire-resistant covers and spaces with airflow for fuel storage. Store fuel in safe containers away from things that can catch fire. Keep heat away to stop overheating. Fire extinguishers should be easy to reach and checked often. Check fuel systems and wires often to stop problems. Ground the generator and do not overload it.

Hospitals must plan for up to 96 hours of emergency use, but they do not need to keep all fuel on site. Deals with suppliers or changing how things run can help. For life safety systems, keep enough fuel on site for 1.5 hours. Diesel, gasoline, and propane each need special storage. Facilities must check fuel quality, use old fuel first, and take care of tanks to keep things working.

The automatic transfer switch (ATS) controls switching between utility and emergency power. NFPA 110 has strict rules for putting in the ATS. The ATS and emergency diesel generator must be in their own room with two-hour fire walls. No other equipment can be in this room. Level 1 ATS cannot share space with normal service equipment unless there is double space. Use fire-resistant wires.

Requirement/Topic | Description |

|---|---|

Location restriction for Level 1 ATS | Level 1 ATS must not be installed in the same room as normal service equipment unless double clearance is provided. |

Fire-resistance rating | Separate room with 2-hour fire-resistance rating for ATS and generator. |

Voltage/amperage limits | Level 1 ATS cannot share a room with service equipment above 150 volts to ground or 1000 amperes. |

Wiring methods | Use fire-resistant wiring such as mineral insulated cable. |

Applicability | Mainly applies to Level 1 systems for critical life safety loads. |

Transfer switches must be made for emergency use, built in a factory, and tested. Mechanical locks stop power sources from mixing. ATS units have timers, engine test timers, and test switches for safe use.

Good maintenance storage keeps the standby engine-generator safe and easy to reach. Keep at least 5 feet between the generator and things that can burn. Use fire-resistant covers. Store fuel in a different area with airflow using safe containers. Cover wires to stop overheating. Fire extinguishers should be close to the generator and checked often. Check fuel lines and wires often. Ground the generator and do not overload circuits. Teach staff about safety and what to do in emergencies. Put in carbon monoxide alarms and make sure there is airflow.

Teach staff how to use the generator safely.

Pick one person to handle generator problems.

Keep a log for maintenance records.

Start the generator often and fix problems fast.

Give hearing protection to workers.

Use covers or enclosures to protect generators from weather.

Tip: Only refuel when the generator is cool to stop fires.

Facility managers need to test the emergency power supply system before it is used. They use a step-by-step process to make sure it is safe and works well. The steps are:

Factory witness testing checks if the generator works right before it leaves the factory.

Site acceptance inspection makes sure the equipment matches what was ordered.

Pre-functional testing checks if the system is installed right and turns on.

Functional performance testing looks at safety devices, automatic controls, and remote communication.

Integrated systems testing, called the "pull-the-plug" test, acts like a real emergency by turning off the power.

Weekly checks help find problems early. Each month, a partial load test runs the generator at about 30% for 30 minutes. Each year, a bigger load test follows NFPA 110 rules. Load banks can be used if real testing is not possible. After ten months, a return visit checks if everything still works well. Ongoing maintenance testing uses ANSI NETA rules to keep the system reliable.

Testing Level | Purpose |

|---|---|

Factory Testing | Checks equipment before it leaves the factory |

Site Inspection | Makes sure specs are right when it arrives |

Pre-Functional | Checks if it is installed and works |

Functional | Tests controls and safety devices |

Integrated | Acts out a real emergency |

Tip: Training staff helps them use the system safely in an emergency.

Good documentation helps keep the system safe and follow the rules. Facility managers make several documents during commissioning:

Owner's Project Requirements (OPR) list what the project needs.

The Commissioning Plan shows what will be done, when, and by whom.

Test procedures and checklists make sure the system works right.

Commissioning reports write down what was found and if rules were met.

Training materials teach staff how to use the system.

Operations & Maintenance (O&M) manuals give instructions for taking care of the system.

ASHRAE says to make system manuals and training papers. These records help staff take care of the emergency power supply system and follow the rules. Documentation also has code checks, permits, and system diagrams. Facility managers keep these records up to date for checks and later use.

Note: Good records help staff act fast in an emergency.

A good generator room keeps people and machines safe. The room must be big enough and have strong fire safety. It also needs air to move well. Every building should follow local rules and talk to experts. Experts can help check the steps and rules. They can help plan a safe generator room. A careful plan keeps power ready for any emergency.

LIYU Group has gas generators and containerized gas generator sets you can trust. They help customers pick the right products for their needs. Contact LIYU Group to learn more or get a quote.

Facility managers need 36 inches of space around each generator. This space lets workers do safe maintenance. It also helps air move around the generator. The rule follows NFPA 110 standards.

Ventilation takes away heat and moisture from the room. It keeps the equipment cool and dry. Good airflow stops overheating and protects electrical parts.

Putting the generator room close to the power distribution room makes wiring shorter. This makes it easier to install everything. It also helps workers reach equipment fast for checks or emergencies.

Concrete Masonry Units (CMU) are strong and resist fire well. They block noise and last a long time. CMU walls meet safety codes and help keep the room quiet.

Facility managers should test generators every week. They should do a partial load test each month and a full load test every year. Regular checks help find problems early.

Tip: Always write down every test and inspection you do.