A generator maintenance checklist helps you keep your generator safe. It also helps your generator work well. When you use a checklist, you protect your money and your home. You can stop power outages from causing problems. Studies show regular generator maintenance is helpful. It means your generator breaks down less often. It also lasts longer and works better. You make your generator safer and more reliable for everyone.

Benefits of Regular Generator Maintenance | How It Helps You |

|---|---|

Preventing Failures | Avoids unexpected breakdowns |

Extending Lifespan | Reduces wear and tear |

Enhancing Safety | Prevents carbon monoxide risks |

If you have a generator, make maintenance a habit. It helps every time you need backup power.

Doing regular generator maintenance stops breakdowns. It helps your generator last longer. It also keeps your home safe when the power goes out.

Check for leaks, fluid levels, battery health, and loose parts every day. This helps you find problems early. It keeps your generator ready to use.

Run your generator once a week. Check the fuel and alarms. This makes sure it works well when you need it.

Do monthly and quarterly jobs like cleaning and checking coolant. Test the battery too. These steps protect your generator from harm. They help it work better.

Keep a maintenance log and follow a set schedule. This helps you track what you do. You can find problems early. It also helps you avoid expensive repairs.

Doing daily checks is the first step in any generator maintenance checklist. These checks help you find problems early. This keeps your generator ready for emergencies. If you use a full checklist, you lower the chance of sudden failures. You also save money on repairs. Here are the important daily steps.

Look at your generator closely every day. This helps you find small problems before they get worse. Use this simple checklist:

Check for oil, fuel, or coolant leaks under and around the generator.

Look at the generator body for dents, cracks, or rust.

Check fuel lines, hoses, and belts for damage or loose parts.

Look at the exhaust for stains or soot.

Listen for strange sounds when the generator is running.

Clear away bugs, nests, or trash from the area.

Tip: Tighten any loose screws, nuts, or bolts you see. Fixing small things now can stop bigger problems later.

These checks help you find leaks, loose parts, or damage. Leaks happen a lot but you can stop them. If you see oil or coolant on the ground, fix it fast. Leaks can make the engine overheat or break. Also, check the emergency stop button. Make sure it is not pressed by mistake. If it is, your generator will not start.

Fluids help your generator work well. If fluids are low or dirty, the generator can overheat or break. Make these fluid checks part of your daily routine:

Use the dipstick to check engine oil. Add more if needed.

Look at coolant levels in the radiator or tank.

Check the fuel gauge and open the tank to see the level.

Look for leaks or wet spots near hoses and tanks.

Checking oil often helps you find leaks or too much oil use. If oil drops a lot, there may be a leak or another issue. Coolant keeps the engine cool. Low coolant can cause big problems. Always use the right oil and coolant for your generator.

Note: Fuel gauge issues can make you lose fuel without knowing. Always check fuel levels before using the generator.

Checking fluids stops many common problems. You will not run out of fuel or overheat the engine. These easy steps help your generator stay reliable.

Your generator needs a good battery to start. Battery problems are a top reason generators do not work. Add these checks to your daily list:

Check battery voltage. It should be fully charged.

Clean battery terminals. Remove any dirt or corrosion.

Make sure all electrical connections are tight.

Look at wires for damage or wear.

Battery/Electrical Task | What to Look For | Why It Matters |

|---|---|---|

Check battery charge | Low voltage, weak battery | Prevents start-up failure |

Clean terminals | Corrosion, dirt | Ensures good electrical contact |

Tighten connections | Loose wires, connectors | Avoids electrical faults |

Inspect wiring | Frayed or damaged wires | Reduces risk of shorts/failure |

A weak or dead battery means no power. Dirty terminals or loose wires can stop your generator from starting. Checking the battery helps you avoid these issues. Also, check circuit breakers and fuses. If a breaker is tripped, do not just reset it. Find out what caused it.

Remember: Taking care of the battery and electrical system keeps your generator ready for emergencies.

Daily checks with a generator maintenance checklist help you find problems early. You protect your generator and make sure it works when you need it. Doing these checks is the best way to stop surprise failures.

You should keep a maintenance log for every generator. This log records all your maintenance work. It helps you track your generator's health and plan future jobs. You can see when you last changed the oil or tested the battery. Logs also help you follow safety rules.

Write down dates, tasks, and what you found.

Track parts used and test results.

Plan future maintenance.

Show you followed the generator maintenance checklist.

Avoid costly downtime by finding problems early.

A good log helps you keep your generator reliable. It supports preventive maintenance and keeps your generator ready for any emergency.

Pro Tip: Use a digital log or app to track tasks and get reminders. This helps you never miss a step in your ideal generator maintenance schedule.

Doing weekly maintenance helps your generator stay ready. You can find problems early and stop generator malfunctions. This protects your money and keeps generator operations working well. Checking every week lets you see issues before they get worse.

You should run your generator once a week. This step checks if it starts and runs well. It also keeps engine parts oiled. You can listen for strange noises and look for smoke or shaking. Running the generator with a load tests its power. You see if it can handle real power needs.

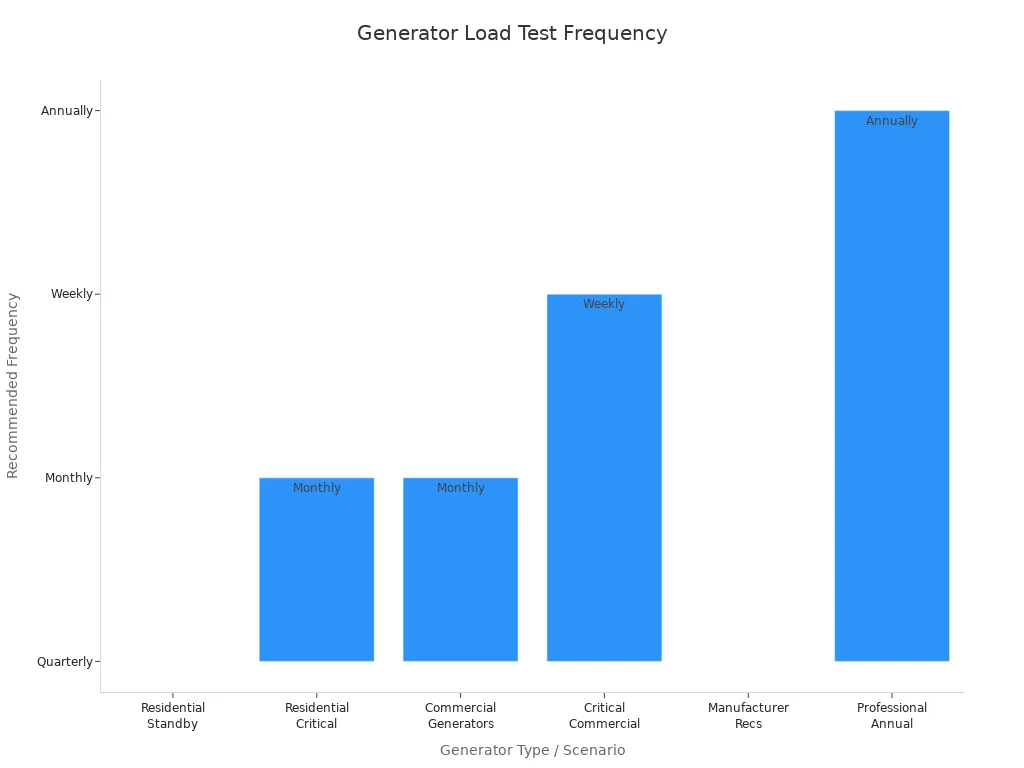

Generator Type / Usage Scenario | Recommended Load Testing Frequency | Duration & Load Details |

|---|---|---|

Residential Standby Generators | At least quarterly (every 3 months) | 30 minutes under load |

Residential Critical Backup | Monthly load testing | 30 minutes under load |

Commercial Generators | Weekly no-load tests; Monthly load tests | Load tests at 50-75% capacity for 30-60 minutes |

Critical Commercial Facilities | Weekly load testing | Load tests at 50-75% capacity for 30-60 minutes |

Manufacturer Recommendations | Monthly no-load tests (10-15 minutes); Quarterly load tests (30-60 minutes at 50-75% capacity); Annual full-load tests (1-2 hours at 100% capacity) | Varies by test type |

Professional Annual Testing | Annually, with specialized equipment and maintenance | Full-load testing with load banks, 1-2 hours |

Tip: Let your generator run for 10-15 minutes each week. Try to test it with a load if you can. This helps it stay ready for emergencies.

Checking fuel every week stops many issues. You make sure the generator has enough fuel and that it is clean. You look for leaks and dirty fuel. This helps stop shutdowns during power outages.

Checking fuel weekly keeps the supply good.

You find low fuel early and do not run out.

You see dirty diesel or blocked filters.

You spot leaks before they cause problems.

Regular checks help stop surprise generator failures.

NFPA 110 rules say you should check fuel weekly. This keeps your generator safe and ready.

Alarms tell you about generator problems. You need to check alarms every week. You look at signals for faults, battery charging, ground faults, and load status. You make sure the generator shows the right running and fault signals.

Maintenance Frequency | Tasks Related to Alarms and Signals on Standby Generators |

|---|---|

Weekly | Battery voltage checks and charger operation checks |

Fault signals show problems.

Load signals show the generator gives power.

Battery charging signals warn of charging issues.

Ground fault signals tell you about electrical trouble.

You check if the generator is running and the switch is in the right place.

Note: Checking alarms keeps your generator safe and ready. You can fix problems before they stop generator operations.

Doing monthly maintenance helps your generator work well. It keeps your generator safe. You find problems early and help it last longer. Follow these steps every month to protect your generator.

Cleaning around the generator each month is important. Dust and dirt can block parts and make them overheat. Trash and things that burn can cause fires. Keeping air areas clear helps the generator run smoothly.

Stop dust and dirt from blocking parts.

Lower fire risk by removing things that burn.

Help the generator work well by clearing air areas.

Find bad stuff early and stop big problems.

Cleaning often can make your generator work up to 98.5% better. It can help your generator last up to 25 years. You also stop sudden problems and keep your generator ready for emergencies.

Check the engine coolant every month to stop overheating. Coolant takes heat away from the engine. If coolant is low from leaks or drying up, cooling does not work well. Look at the radiator, hoses, fans, and water pump for leaks or damage.

Coolant takes heat away and keeps the engine cool.

Low coolant can make the engine too hot and break.

Monthly checks help you add coolant and check if it is good.

Look at all parts to keep coolant moving right.

NFPA 110 says you need the right coolant level for good generator work. Testing coolant flow and radiator heat under load helps you find overheating before it causes problems.

A good battery charger helps your generator start when needed. Check battery cables and how much liquid is inside. Clean off rust from battery ends with a toothbrush and baking soda. Test the battery to see if it is healthy.

Look for leaks, broken wires, smells, or damage.

Turn on the system and check the lights.

Plug in things to see if battery backup works.

Pretend the power goes out and watch what happens.

Turn power back on and check if the battery charges.

Write down what you check and test.

Battery Charger Task | Purpose |

|---|---|

Inspect cables and terminals | Stop problems when starting |

Test electrolyte levels | Make sure battery is healthy |

Check charger operation | Keep generator ready |

Record results | Track what you did |

Checking the battery charger every month helps you stop start-up problems. It keeps your generator ready for emergencies.

Check the generator enclosure every three months. This keeps your generator safe and working well. Look for trash inside and outside the enclosure. Take out leaves, dirt, or garbage. Clean the outside to stop dust from building up. Make sure air can move through the vents. Blocked vents can make the generator too hot. Look for leaks, cracks, or other damage. Check for rust on metal parts. Rust can let water in and hurt the generator.

Take out trash from inside and outside the enclosure.

Clean all parts and connections.

Look for leaks, cracks, and rust.

Make sure vents are open for good airflow.

Keeping the enclosure clean and fixing damage helps your generator last longer and work better.

Check the battery every three months to keep your generator working. Test if the battery is healthy and check the connections. Look at the float voltage and measure specific gravity for lead-acid batteries. Write down your results and fix any problems you find. These checks help you find battery problems before they stop your generator. Rules like NERC PRC-005 and IEEE say you must check batteries often. A strong battery helps your generator start during power outages. If you skip these checks, you might lose power when you need it most.

Battery Check Item | Why It Matters |

|---|---|

State of health | Shows if the battery is strong |

Connection integrity | Prevents power loss |

Float voltage | Keeps battery charged |

Specific gravity | Checks battery condition |

Checking the battery often stops surprise problems and keeps your generator ready.

Check the exhaust system every three months. Rust is a common problem. It can hurt pipes and silencers, especially in wet places. Wet stacking happens when the generator runs with low power. You may see black smoke or oily marks. This means oil and fuel build up in the exhaust. Old engines can backfire. Backfires make loud sounds and may crack or bulge the exhaust. Exhaust gas leaks often start at joints or connectors. These leaks are dangerous because they let out hot gases and carbon monoxide.

Look for rust on pipes and silencers.

Check for black smoke or oily marks (wet stacking).

Watch for bulges or cracks (backfires).

Check joints for leaks or burnt insulation.

A good exhaust system keeps your generator safe and protects people nearby.

Check your generator's engine coolant and oil every six months. These checks keep your generator safe. They help stop overheating. Look at fluid levels and check for leaks. Fix low coolant or dirty oil right away. This keeps the engine healthy.

Look at coolant lines for leaks.

Check connections for leaks.

Use the dipstick to check oil levels.

Look at hoses and connectors in the lubrication system.

Check for oil leaks near the engine.

Make sure the coolant heater works.

Clean the air cleaner units.

Check drive belts for damage.

Take out debris from the enclosure.

If oil or coolant is dirty, replace them. Follow the manufacturer's instructions. Drain old oil and change the oil filter. Fill with new oil. Test coolant to see if it protects the engine. Take samples of coolant and oil to find problems early. Check the exhaust system and air induction piping. This helps keep airflow strong.

Doing these checks helps you stop engine damage. Your generator will be ready for emergencies.

Your generator needs a strong battery to start. Do a full battery check twice a year. This check looks at the battery charger, cables, and connections. Test the electrolyte level and specific gravity. Make sure connectors and cables are clean and tight.

Maintenance Interval | Battery Charger / Battery Task Description |

|---|---|

Monthly | Visual inspection of battery and charger |

Bi-Annual | Full battery diagnostic check |

Annual | Load testing of batteries |

Look at the DC electrical system and control panel. Check for corrosion or loose wires. Write down your results to track battery health. Fix any problems before they stop your generator.

Battery tests help you stop start-up failures. They keep your generator working well.

Doing yearly maintenance helps your generator stay safe. It also makes sure your generator works well. You should do these tasks every year. This stops breakdowns and helps your generator last longer. A yearly inspection finds hidden problems before they get worse.

Change the oil and oil filter every year. Do this after 100-200 hours of use. If you use your generator a lot, change the oil more often. Always put in a new oil filter when you change the oil. Check oil levels between changes. Follow your owner's manual for steps.

Change oil after the first 25-50 hours.

Change oil and filter after the first 100 hours.

Change oil and filter every 200 hours or once a year.

Always check oil before you start the generator.

Check the air intake system every year. Clean or replace the air filter to keep airflow strong. Take out dirt and debris from the intake area. This helps your generator run well and stops engine damage. A clean air intake system helps your generator work better and saves money on repairs.

Let a certified technician check the electrical system and wiring. Replace old spark plugs and filters. Look for loose wires and broken insulation. Make sure the battery is charged and connections are clean. Test the battery under load to see if it works well.

Look at wiring for breaks or loose connections.

Put in new spark plugs and filters.

Check battery charge and connections.

Take water out of the fuel tank.

A load bank test checks if your generator can handle real power needs. This test uses a fake load to bring the generator to full power. It helps you find problems early and stops engine damage from not using the generator enough. Load bank testing also burns off carbon deposits and keeps the cooling system working.

Test your generator by pretending there is a power outage. Turn off the main power and let the generator run with a load. Watch for smooth running and quick power transfer. This test shows if your generator will work in an emergency.

Clean your generator inside and outside. Take dust off the transfer switch, louvers, and fan blades. Clean battery terminals and use anti-corrosion spray. Look at and clean the enclosure and air intake filter. Put in a new air filter if it is dirty. Cleaning helps your generator work well and stops rust.

Getting a yearly inspection from a professional keeps your generator ready for emergencies.

A generator inspection checklist helps you keep your generator safe and reliable. You can use this checklist to spot problems early and make sure your generator works when you need it most. Follow these steps to cover all important parts of your generator.

Start by looking at the outside of your generator. Make sure it sits on a stable surface. Check that the housing is not cracked or damaged. Clear away any trash or leaves near the vents. Look for signs of leaks or rust. Make sure all guards and covers are in place.

Check the oil level using the dipstick. Add oil if it is low. Look at the oil filter for dirt or leaks. Change the oil and filter if they look dirty or if it has been a long time since the last change. Clean oil helps your generator run smoothly.

Look at the coolant level in the tank or radiator. Add coolant if it is low. Check hoses and connections for leaks or cracks. Make sure the radiator fins are clean and not blocked. A good coolant system keeps your generator from overheating.

Check the fuel level and make sure the fuel cap is tight. Look at fuel lines for cracks or leaks. Inspect the fuel filter for dirt. Make sure fuel can reach the generator without any blockages. Clean fuel keeps your generator running well.

Look at the battery terminals for corrosion. Clean them if you see any white or green buildup. Make sure the battery is charged. Check that cables are tight and not damaged. A strong battery helps your generator start every time.

Inspect the exhaust pipe and muffler for rust or holes. Make sure the exhaust points away from doors and windows. Look for black smoke or oily marks. Check that the carbon monoxide detector works. A safe exhaust system protects you from harmful gases.

Take out the air filter and look for dirt or dust. Clean or replace it if needed. A clean air filter helps your generator get enough air to run well.

Check all wires for damage or loose connections. Look at the control panel and circuit breakers. Test the automatic transfer switch. Make sure all warning lights and gauges work. Good electrical parts help your generator deliver power safely.

Tip: Use your generator inspection checklist every month. Write down what you find in a log. This helps you track changes and spot problems early.

Inspection Item | What to Check For | Why It Matters |

|---|---|---|

Oil and Filter | Level, leaks, dirt | Prevents engine damage |

Coolant System | Level, leaks, blockages | Stops overheating |

Fuel System | Level, leaks, filter | Ensures steady operation |

Battery | Charge, corrosion, cables | Reliable start-up |

Exhaust System | Rust, leaks, smoke | Safety and air quality |

Air Filter | Dirt, damage | Keeps airflow strong |

Electrical System | Wires, switches, lights | Safe power delivery |

Backup generator maintenance makes sure your generator is ready for emergencies. You must do special steps because backup generators need to work right away when the power goes out. This is different from regular generator care. Backup generator maintenance means you test with a load often. You also follow strict service times and do safety checks. You test the transfer switch and automatic start system many times. You check filters, belts, coolant, batteries, and control panels on a set schedule.

Changing oil and filters helps your generator run well. Change the oil after the first 25 hours of use. After that, change it every 100 to 200 hours or once a year. Portable generators need oil changes every 50 to 100 hours. Always put in a new oil filter when you change the oil. If you use your generator in hot, dusty, or wet places, change the oil more often. Look at the owner's manual for the right schedule for your model.

Tip: Clean oil keeps the engine safe and helps it last longer.

Oil Change Frequency Table

Generator Type | First Oil Change | Regular Oil Change Interval |

|---|---|---|

Standby Generator | 25 hours | 100-200 hours or yearly |

Portable Generator | 25 hours | 50-100 hours |

A clean air filter helps your generator get enough air. Check the air filter every time you change the oil. Replace it if you see dirt or damage. Dust and debris can block air and make the engine work harder. A new air filter keeps your generator running strong.

Check the air filter during each oil change.

Replace it if it is dirty or damaged.

Use the correct filter for your generator model.

Belts and hoses move power and fluids inside your generator. You need to look at them often. Check for cracks, wear, or loose parts. Replace any belt or hose that looks old or broken. Tight belts and good hoses help your generator work well in emergencies.

Note: Old belts or leaking hoses can stop your generator from working when you need it most.

Cleaning keeps your generator safe. Take away dust, leaves, and debris from the enclosure. Wipe the control panels and battery terminals. Clean air vents so heat can get out. You should also look for rust or corrosion. Clean parts help your generator last longer and stay ready for backup power.

Backup Generator Maintenance Checklist

Run monthly load tests using real power.

Change oil and filters on time.

Replace air filters when needed.

Check and replace belts and hoses.

Clean all parts and look for rust.

Test the transfer switch and automatic start system.

Follow safety rules for fire and fault protection.

Regular backup generator maintenance helps you feel safe. You know your generator will work when you need it most.

You need to keep a maintenance log for your generator. This log helps you track every check and repair. It shows when you last changed the oil or checked the battery. You can use a notebook, a spreadsheet, or a digital app. A good log makes it easy to spot patterns or problems. If you see the same issue many times, you know it needs more attention. You can also show your log to a technician. This helps them understand your generator's history.

Tip: Write down the date, task, and any notes each time you work on your generator.

Sample Maintenance Log Table

Date | Task | Notes |

|---|---|---|

2024-03-01 | Oil Change | Oil was dark |

2024-03-15 | Battery Check | Voltage normal |

2024-04-01 | Air Filter Cleaned | Filter replaced |

You should set reminders for each generator task. Reminders help you stay on track. You can use your phone, a calendar, or a maintenance app. Set alerts for daily, weekly, and monthly checks. This way, you never miss a step. Reminders make it easier to keep your generator ready for emergencies.

Use phone alarms for daily checks.

Mark weekly and monthly tasks on a wall calendar.

Try a digital app for automatic alerts.

Staying on schedule keeps your generator reliable.

Consistency is key for good generator care. When you follow the same steps each time, you build strong habits. You lower the risk of missing important tasks. You also make it easier to spot changes or new problems. If you always check the same things, you notice when something looks different. This helps you fix small issues before they grow.

Stick to your checklist every time.

Review your log often.

Update your schedule if you add new tasks.

Consistent care helps your generator last longer and work better.

Following a generator maintenance checklist helps you stay safe. It also keeps your equipment working well. You stop sudden breakdowns by checking fluids and battery connections. Running tests helps you find problems early. Load bank testing and professional inspections make things safer. Keeping good records and using digital tools helps you track tasks. You can spot problems before they get worse. If you learn to notice warning signs, you fix issues fast. Doing regular checks helps your generator last longer. It also protects your money.

Routine checks help stop surprise shutdowns.

Load bank tests show if the generator works well.

Professional checks help you find hidden problems.

Digital tools help you remember tasks.

Taking care of your generator helps you feel calm. You know it will work when you need it.

LIYU Group has advanced gas generators and containerized sets. You can look at their products for your power needs. Try clicking here to learn more about LIYU Group's reliable choices.

You need to follow a regular schedule. Check your generator every day, week, month, and year. Write down each task in a maintenance log. Regular service helps your generator last longer. It also helps it work better.

If you skip maintenance, your generator might not work in an emergency. You could see leaks or battery trouble. The engine might get damaged. Repairs can cost a lot. You might even face safety problems.

You can do simple jobs like checking fluids and cleaning. You can also run basic tests. For harder jobs, call a professional. Always use the owner's manual to stay safe.

Watch for these signs:

Weird noises

Leaks

Hard to start

Warning lights

Fix any problems as soon as you see them.

A load bank test shows if your generator can handle real power. It helps you find hidden problems. This test keeps your generator ready for emergencies.

Liyu Group Participates in Madagascar Government Delegation Forum

Liyu Group Invited to the China-Zambia Green Power Cooperation Forum

What Types of Facilities Benefit From Used Commercial Generators?

How Fuel Polishing Improves The Efficiency of Diesel Generators?

How Tariffs Could Potentially Impact The Generator Industry?